Call Us Now08045816523

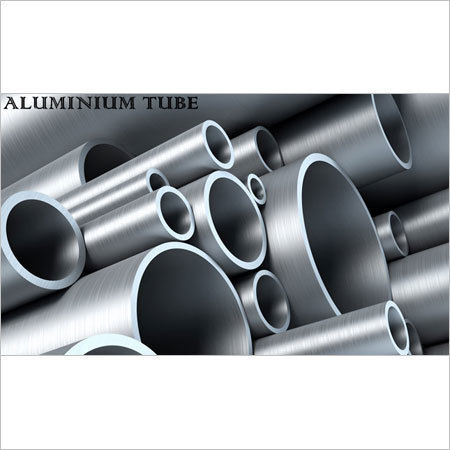

Aluminium Pipes

220 INR/Kilograms

Product Details:

- Thickness 0.5 mm to 20 mm

- Usage & Applications Construction, architecture, automotive, furniture, industrial

- Outer Diameter As per specification

- Diameter Custom (Standard: 9 mm to 300 mm)

- Features Light weight, corrosion resistant, durable, high strength

- Finish Mill, anodized or powder coated

- Size 1/2 inch to 10 inches or as required

- Click to View more

X

Aluminium Pipes Price And Quantity

- 220 INR/Kilograms

- 100 Kilograms

- Excellent

- Seamless or welded

- 100% recyclable

- Plain End, Beveled, Threaded

- Good machinability

- Plastic wrapping, wooden box, steel frame

- ±0.05 mm

- Yes

- Available

- Varies with size and thickness

- 660°C

- Excellent thermal and electrical conductivity

- ASTM B241, EN AW-6060

- 2.7 g/cm³

Aluminium Pipes Product Specifications

- Construction, architecture, automotive, furniture, industrial

- 0.5 mm to 20 mm

- As per specification

- 1/2 inch to 10 inches or as required

- Mill, anodized or powder coated

- High tensile

- 60-110 HB

- Custom (Standard: 9 mm to 300 mm)

- Light weight, corrosion resistant, durable, high strength

- Customized

- Round

- Custom (2 m to 6 m standard)

- 6061, 6082, 6063

- Silver

- 6061, 6082, 6063 or as per requirement

- Yes

- Round

- Mill Finish

- Aluminium Pipe

- T6

- Aluminium

- Extruded

- Excellent

- Seamless or welded

- 100% recyclable

- Plain End, Beveled, Threaded

- Good machinability

- Plastic wrapping, wooden box, steel frame

- ±0.05 mm

- Yes

- Available

- Varies with size and thickness

- 660°C

- Excellent thermal and electrical conductivity

- ASTM B241, EN AW-6060

- 2.7 g/cm³

Aluminium Pipes Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 100000 Kilograms Per Day

- 1 Days

- All India

Product Description

Aluminium pipes, supplied by us are the excellent engineering materials. These are indisputable choices for assorted applications. These are light, strong and have high strength-to-weight ratio. Aluminium pipes we deal in are resilient in nature and stay ductile at low temperatures. They are functional as corrosion resistant pipes of non-toxic make. These are appreciable for their heat conducting as well as reflective properties. Offered are the electrically conducting pipes of non-magnetic make. They are non-sparking and non-combustible pipes.

Superior Conductivity & Strength

These aluminium pipes are distinguished by excellent thermal and electrical conductivity, making them suitable for applications that require efficient energy transfer. Their high tensile strength and shock resistance ensure performance even in demanding environments such as automotive or industrial settings.

Customizable Dimensions & Finishes

Offered in a wide size range (1/2 inch to 10 inches, or custom), and thickness options up to 20 mm, our pipes accommodate specific project requirements. Choose from plain end, beveled, or threaded finishes, with mill, anodized, or powder-coated surfaces to meet aesthetic and functional needs.

Sustainable & Quality Assured

Manufactured in adherence to international standards (ASTM B241, EN AW-6060), these pipes are 100% recyclable and crafted using extruded processes for optimal machinability. Packaging options include plastic wrap, wooden boxes, or steel frames, ensuring safety during transport and storage.

FAQs of Aluminium Pipes:

Q: How are aluminium pipes fabricated and what end types are available?

A: Aluminium pipes are primarily manufactured using the extrusion process, which allows for precise control of dimensions and surface quality. Based on requirements, pipes can be supplied with plain ends, beveled ends, or threaded ends, accommodating various installation and joining methods.Q: What makes these aluminium pipes suitable for electrical and thermal applications?

A: With excellent thermal and electrical conductivity, these pipes efficiently transfer heat and electricity, making them ideal for applications in power, construction, and architectural projects where energy transmission is crucial.Q: When should I consider using seamless versus welded aluminium pipes?

A: Seamless pipes are preferable for high-pressure or critical structural applications, offering superior strength and uniformity. Welded pipes are suitable for general uses where internal or external pressure is moderate and cost-efficiency is a priority.Q: Where can these aluminium pipes be utilized effectively?

A: These pipes are widely used in construction, architecture, automotive, furniture, and various industrial sectors due to their lightweight, high strength, corrosion resistance, and excellent machinability.Q: What tolerances and customization options are offered?

A: Our aluminium pipes offer a precise dimensional tolerance of 0.05 mm. Customization is available for diameter (9 mm to 300 mm), thickness (0.5 mm to 20 mm), length (26 meters standard, other sizes on request), surface finish, and material grade as per project needs.Q: How does the aluminium pipes recyclability benefit my project?

A: Being 100% recyclable, using these aluminium pipes supports sustainable practices, reduces material costs, and helps achieve environmental compliance without sacrificing quality or performance.Q: What are the advantages of choosing mill finish, anodized, or powder-coated surfaces?

A: Mill finish is the standard surface as-extruded, suitable for many industrial purposes. Anodized surfaces offer enhanced corrosion resistance and aesthetic appeal, while powder coating provides vibrant color options and added durability for outdoor or decorative use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese