Aluminium Alloy Plate 7075

Product Details:

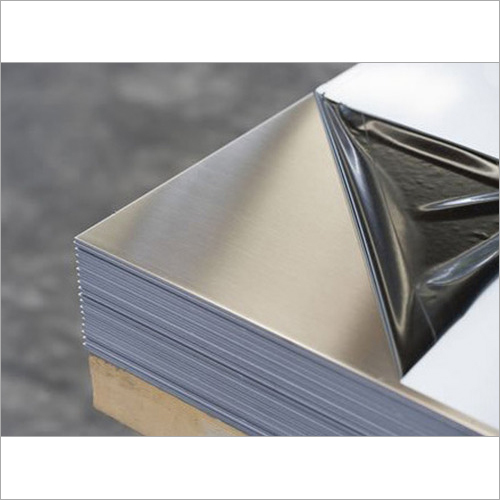

- Product Type Alloy Plate

- Shape Rectangular

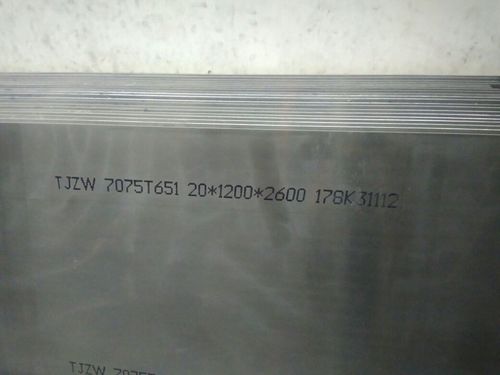

- Grade 7075

- Temper T6

- Surface Treatment Mill Finish

- Color Silver

- Click to View more

Aluminium Alloy Plate 7075 Price And Quantity

- 500.00 - 700.00 INR/Kilograms

- 100 Kilograms

Aluminium Alloy Plate 7075 Product Specifications

- Mill Finish

- T6

- 7075

- Rectangular

- Alloy Plate

- Silver

Aluminium Alloy Plate 7075 Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 100000 Kilograms Per Day

- 1 Days

- All India

Product Description

The main alloying element in 7075 is zinc. Aluminium Alloy 3.4365 (7075) was the first Al-Zn-Mg-Cu high-strength alloy that utilized the addition of chromium as an alloying element, resulting in good stress-corrosion cracking resistance for sheet products. Although 7075 Aluminum has no weldability, a low level of corrosion resistance and only offers average performance this alloy offers considerable fatigue strength. With a high strength-to-density ratio, 7075 alloys are often used in applications such as rock climbing equipment, hang glider airframes, and military rifles. Not surprisingly, 7075 aluminum is still considered the go-to alloy for the aircraft and aerospace industries today.

If you are looking for 7075 T651 aluminum we are here for you. With more than ninety years of successful metals distribution under our belt, the aluminum experts at Howard Precision Metals have acquired a wealth of knowledge regarding the properties of aluminum and truly understand how aluminum will perform when used in a wide range of industries. We are the preferred 7075 aluminum plate suppliers for a number of aircraft and aerospace companies, as well as providing 7075 T6 aluminum to companies in the engineering, energy, automotive and construction industries. No matter what the nature of your project, we have the 7075 T651 aluminum for sale that you need.

7075 aluminum is well-known for its fatigue resistance. An economical choice for applications where frequent movement, pressure changes or other stresses are likely to be a regular feature, the 7075 aluminum alloy is a preferred choice for everything from bicycle parts to firearms.

7075 Aluminum Applications

In terms of strength, 7075 Aluminum is near the top of the list among aluminum alloys manufactured for the needs of consumer and industrial markets. Among other 7XXX alloys, alloy 7075 exists as a standard with a solid mix of properties suitable for aircraft and aerospace applications. In particular, this alloy utilized in various forms, including as 7075 aluminum bar, is well-suited for use in parts that endure high-stress levels. The strength properties of alloy 7075 are beneficial for the manufacture of items such as aircraft structures, military-grade rifles, bicycle parts and equipment, and plastic industry moulds.

7075 T651 Aluminum

An aluminium alloy best suited for aerospace and aviation applications is 7075 T651. This tempered alloy has a high tensile strength which makes it particularly applicable for certain high-strength applications.

Kindly send your requirements on sales@maharashtrametal.co.in

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese